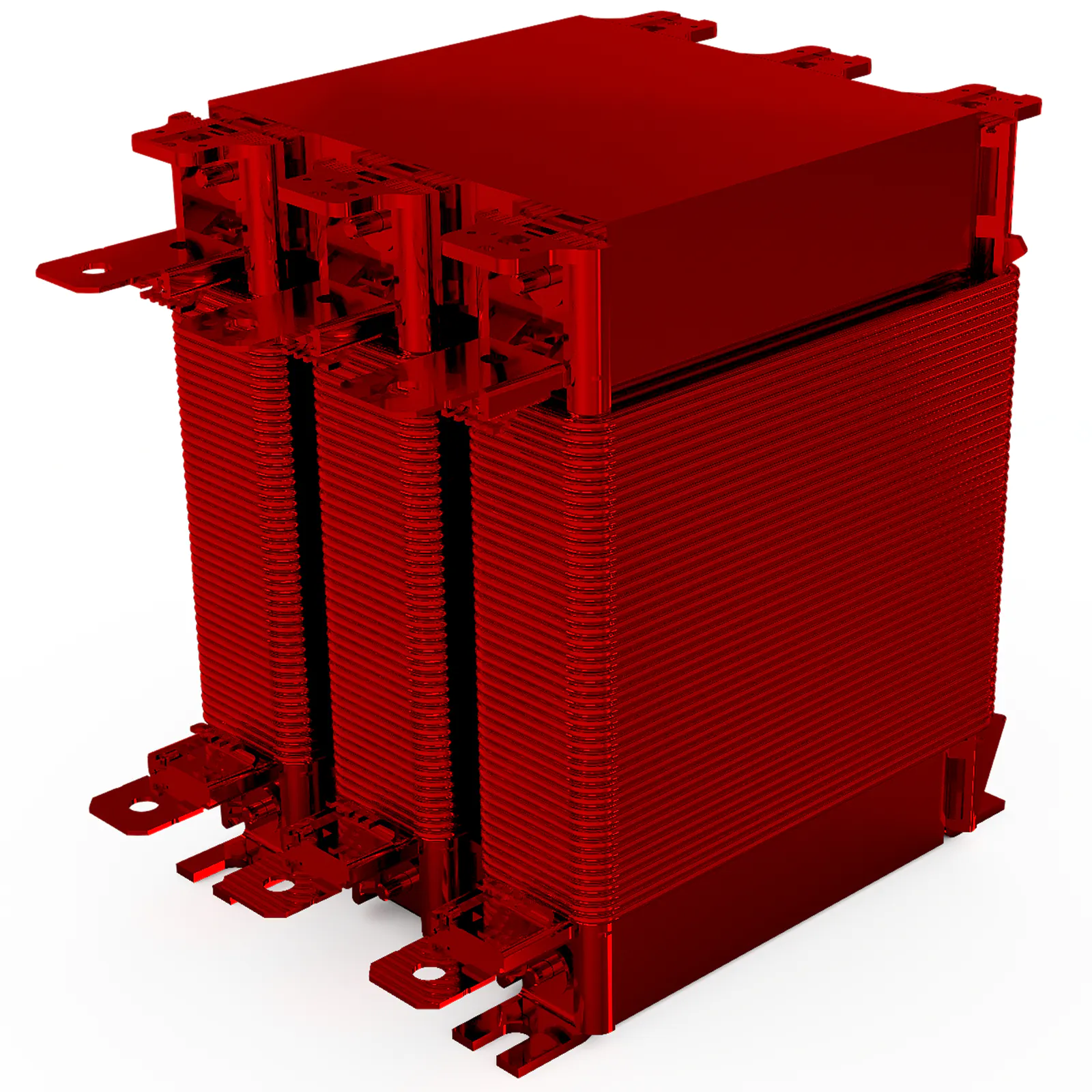

RTFX

Features

Anti-flash varnish finish, offering:

- Protection against corrosive environments

- Increase of electrical isolation

- High compression capacity

- Reduction of noise level

- Increase of product's lifespan

Safety class I

Includes thermal protection against overtemperatures

Possibility of tailor-made manufacturing

Technical remarks about the use of detuned reactors:

- They avoid resonance between the feeding transformer's inductance and the capacitance of capacitors' bank

- They eliminate overvoltages and overcurrents either from the transformer and from the capacitors' bank

- They protect capacitors against harmonics avoiding early aging

- They limit conection peaks of the capacitors' bank increasing their lifespan and reducing microcuts in the fedding voltage

Applications

- RTFX inductances are designed to protect in front of harmonics capacitor banks power factor correctors.

- The inductances tuned to 189Hz are the most common

Available accessories

- PT100 probe.

- PTC probe

- Different terminals

Downloads

| RTFX5 » | RTFX10 » | RTFX12.5 » | RTFX15 » | RTFX20 » | RTFX25 » | RTFX30 » | RTFX40 » | RTFX50 » | RTFX60 » | RTFX80 » | RTFX100 » | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Line voltage | 400 V | 400 V | 400 V | 400 V | 400 V | 400 V | 400 V | 400 V | 400 V | 400 V | 400 V | 400 V |

| Capacitor rating | 5 kvar (440 V, 50 Hz) | 10 kvar (440 V, 50 Hz) | 12,5 kvar (440 V, 50 Hz) | 15 kvar (440 V, 50 Hz) | 20 kvar (440 V, 50 Hz) | 25 kvar (440 V, 50 Hz) | 30 kvar (440 V, 50 Hz) | 40 kvar (440 V, 50 Hz) | 50 kvar (440 V, 50 Hz) | 60 kvar (440 V, 50 Hz) | 80 kvar (440 V, 50 Hz) | 100 kvar (440 V, 50 Hz) |

| Effective rating | 4,4 kvar | 8,9 kvar | 11,1 kvar | 13,3 kvar | 17,8 kvar | 22,2 kvar | 26,7 kvar | 35,5 kvar | 44,4 kvar | 53,3 kvar | 71,1 kvar | 88,8 kvar |

| Rated current | 6,8 A | 13,6 A | 17,0 A | 20,4 A | 27,2 A | 34,0 A | 40,8 A | 54,4 A | 68 A | 82 A | 109 A | 136 A |

| Reactor | 8,6258 mH (50 Hz) | 4,3129 mH (50 Hz) | 3,4503 mH (50 Hz) | 2,8753 mH (50 Hz) | 2,1565 mH (50 Hz) | 1,7252 mH (50 Hz) | 1,4376 mH (50 Hz) | 1,0782 mH (50 Hz) | 0,8626 mH (50 Hz) | 0,7188 mH (50 Hz) | 0,5391 mH (50 Hz) | 0,4313 mH (50 Hz) |

| Inductance tolerance | 3% | 3% | 3% | 3% | 3% | 3% | 3% | 3% | 3% | 3% | 3% | 3% |

| Resonance frequency | 189 Hz (p 7%) | 189 Hz (p 7%) | 189 Hz (p 7%) | 189 Hz (p 7%) | 189 Hz (p 7%) | 189 Hz (p 7%) | 189 Hz (p 7%) | 189 Hz (p 7%) | 189 Hz (p 7%) | 189 Hz (p 7%) | 189 Hz (p 7%) | 189 Hz (p 7%) |

| Harmonic currents | I3 – 8%, I5 – 31%, I7 – 13% | I3 – 8%, I5 – 31%, I7 – 13% | I3 – 8%, I5 – 31%, I7 – 13% | I3 – 8%, I5 – 31%, I7 – 13% | I3 – 8%, I5 – 31%, I7 – 13% | I3 – 8%, I5 – 31%, I7 – 13% | I3 – 8%, I5 – 31%, I7 – 13% | I3 – 8%, I5 – 31%, I7 – 13% | I3 – 8%, I5 – 31%, I7 – 13% | I3 – 8%, I5 – 31%, I7 – 13% | I3 – 8%, I5 – 31%, I7 – 13% | I3 – 8%, I5 – 31%, I7 – 13% |

| Thermal overload factor | 0,05 | 0,05 | 0,05 | 0,05 | 0,05 | 0,05 | 0,05 | 0,05 | 0,05 | 0,05 | 0,05 | 0,05 |

| Frequency | 50 Hz | 50 Hz | 50 Hz | 50 Hz | 50 Hz | 50 Hz | 50 Hz | 50 Hz | 50 Hz | 50 Hz | 50 Hz | 50 Hz |

| Protection degree | IP-00 | IP-00 | IP-00 | IP-00 | IP-00 | IP-00 | IP-00 | IP-00 | IP-00 | IP-00 | IP-00 | IP-00 |

| Cooling | AN | AN | AN | AN | AN | AN | AN | AN | AN | AN | AN | AN |

| Ambient temperature | 45ºC | 45ºC | 45ºC | 45ºC | 45ºC | 45ºC | 45ºC | 45ºC | 45ºC | 45ºC | 45ºC | 45ºC |

| Temperature rise | Class F – 155ºC | Class F – 155ºC | Class F – 155ºC | Class F – 155ºC | Class F – 155ºC | Class F – 155ºC | Class F – 155ºC | Class F – 155ºC | Class F – 155ºC | Class F – 155ºC | Class F – 155ºC | Class F – 155ºC |

| Insulation | Clase H – 180 ºC | Clase H – 180 ºC | Clase H – 180 ºC | Clase H – 180 ºC | Clase H – 180 ºC | Clase H – 180 ºC | Clase H – 180 ºC | Clase H – 180 ºC | Clase H – 180 ºC | Clase H – 180 ºC | Clase H – 180 ºC | Clase H – 180 ºC |

| Windings | Class HC – 200 ºC | Class HC – 200 ºC | Class HC – 200 ºC | Class HC – 200 ºC | Class HC – 200 ºC | Class HC – 200 ºC | Class HC – 200 ºC | Class HC – 200 ºC | Class HC – 200 ºC | Class HC – 200 ºC | Class HC – 200 ºC | Class HC – 200 ºC |

| Test voltage | 3 kV (1 min, 50 Hz) | 3 kV (1 min, 50 Hz) | 3 kV (1 min, 50 Hz) | 3 kV (1 min, 50 Hz) | 3 kV (1 min, 50 Hz) | 3 kV (1 min, 50 Hz) | 3 kV (1 min, 50 Hz) | 3 kV (1 min, 50 Hz) | 3 kV (1 min, 50 Hz) | 3 kV (1 min, 50 Hz) | 3 kV (1 min, 50 Hz) | 3 kV (1 min, 50 Hz) |

| Includes | Bimetal thermal protection | Bimetal thermal protection | Bimetal thermal protection | Bimetal thermal protection | Bimetal thermal protection | Bimetal thermal protection | Bimetal thermal protection | Bimetal thermal protection | Bimetal thermal protection | Bimetal thermal protection | Bimetal thermal protection | Bimetal thermal protection |

| Standards | IEC/EN/UNE-EN 60076-6, CE | IEC/EN/UNE-EN 60076-6, CE | IEC/EN/UNE-EN 60076-6, CE | IEC/EN/UNE-EN 60076-6, CE | IEC/EN/UNE-EN 60076-6, CE | IEC/EN/UNE-EN 60076-6, CE | IEC/EN/UNE-EN 60076-6, CE | IEC/EN/UNE-EN 60076-6, CE | IEC/EN/UNE-EN 60076-6, CE | IEC/EN/UNE-EN 60076-6, CE | IEC/EN/UNE-EN 60076-6, CE | IEC/EN/UNE-EN 60076-6, CE |

| Mounting | Screws | Screws | Screws | Screws | Screws | Screws | Screws | Screws | Screws | Screws | Screws | Screws |

| Weight | 5,6 kg | 7,6 kg | 9,5 kg | 11,1 kg | 12,1 kg | 14 kg | 16,8 kg | 20,9 kg | 22,9 kg | 25,8 kg | 33,2 kg | 40,8 kg |

| Dimensions (AxBxCxDxE) | 150x111x185x85x100 mm 9Ø | 150x126x185x100x100 mm 9Ø | 150x141x185x115x100 mm 9Ø | 180x126x220x100x120 mm 9Ø | 180x131x220x105x120 mm 9Ø | 180x141x220x115x120 mm 9Ø | 180x156x220x130x120 mm 9Ø | 180x176x220x150x120 mm 9Ø | 180x186x220x160x120 mm 9Ø | 180x201x220x175x120 mm 9Ø | 240x200x320x135x160 mm 9Ø | 240x220x320x160x160 mm 9Ø |

| Quote / Buy |

How to buy?

You can buy online if you are located in one of this countries: Austria, Croatia, Czech Republic, Finland, France, Germany, Greece, Hungary, Ireland, Italy, Lithuania, Luxembourg Poland, Slovakia and Sweden.

Special fabrications

We build transformers and inductive elements tailored to your needs.

Explain your needs and our engineers will create a solution adapted to your company.