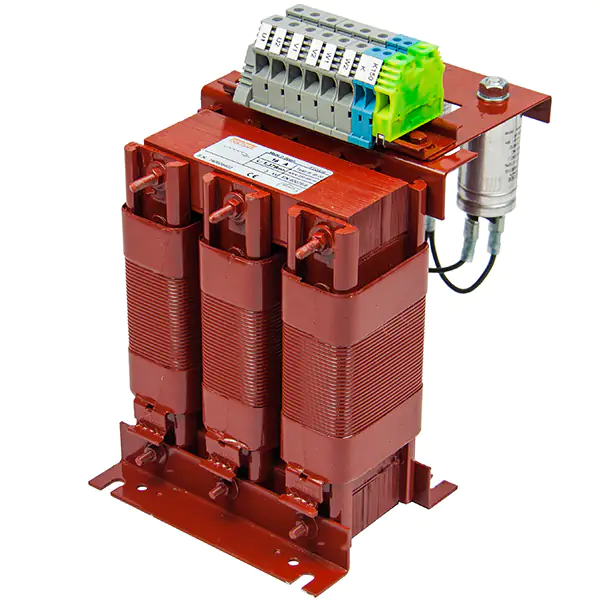

FTOX

Features

Reactor

Anti-flash varnish finish, offering:

- Protection against corrosive environments

- Increase of electrical isolation

- High compression capacity

- Reduction of noise level

- Increase of product's lifespan

Maximum output voltage 2Un (800V)

Safety class I

Includes thermal protection against overtemperatures

Possibility of tailor-made manufacturing

Technical remarks about the use of line reactors:

- Attenuation of voltage peaks in the output of the converter, protecting against premature degradation of the dielectrical parts of the motor

- Reduction of the reflection effect due to the length of the cables between the converter and the motor. This effect amplifies voltage values in the terminals of the motor

- It is recomended to use these inductances for lengths over 50 m from the converter to the motor

Downloads

| FTOX2.5 » | FTOX4 » | FTOX5 » | FTOX6.3 » | FTOX8 » | FTOX10 » | FTOX12.5 » | FTOX16 » | FTOX20 » | FTOX25 » | FTOX31.5 » | FTOX40 » | FTOX50 » | FTOX63 » | FTOX80 » | FTOX100 » | FTOX125 » | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Rated current | 2,5 A | 4 A | 5 A | 6,3 A | 8 A | 10 A | 12,5 A | 16 A | 20 A | 25 A | 31,5 A | 40 A | 50 A | 63 A | 80 A | 100 A | 125 A |

| Motor rating | 0,75 kW / 1 CV | 1,1 kW / 1,5 CV | 1,5 kW / 2 CV | 2,2 kW / 3 CV | 3 kW / 4 CV | 4 kW / 5,5 CV | 5,5 kW / 7,5 CV | 6,5 kW / 8,7 CV | 7,5 kW / 10 CV | 11 kW / 15 CV | 15 kW / 20 CV | 18,5 kW / 25 CV | 22 kW / 30 CV | 30 kW / 40 ºCV | 37 kW / 50 CV | 45 kW / 60 CV | 55 kW / 75 CV |

| Line voltage | 380 – 460 V | 380 – 460 V | 380 – 460 V | 380 – 460 V | 380 – 460 V | 380 – 460 V | 380 – 460 V | 380 – 460 V | 380 – 460 V | 380 – 460 V | 380 – 460 V | 380 – 460 V | 380 – 460 V | 380 – 460 V | 380 – 460 V | 380 – 460 V | 380 – 460 V |

| Reactor | 8,821 mH (50 Hz) | 5,513 mH (50 Hz) | 4,411 mH (50 Hz) | 3,501 mH (50 Hz) | 2,757 mH (50 Hz) | 2,205 mH (50 Hz) | 1,764 mH (50 Hz) | 1,378 mH (50 Hz) | 1,103 mH (50 Hz) | 0,882 mH (50 Hz) | 0,700 mH (50 Hz) | 0,551 mH (50 Hz) | 0,441 mH (50 Hz) | 0,350 mH (50 Hz) | 0,276 mH (50 Hz) | 0,221 mH (50 Hz) | 0,176 mH (50 Hz) |

| Voltage drop | 3% (50 Hz) | 3% (50 Hz) | 3% (50 Hz) | 3% (50 Hz) | 3% (50 Hz) | 3% (50 Hz) | 3% (50 Hz) | 3% (50 Hz) | 3% (50 Hz) | 3% (50 Hz) | 3% (50 Hz) | 3% (50 Hz) | 3% (50 Hz) | 3% (50 Hz) | 3% (50 Hz) | 3% (50 Hz) | 3% (50 Hz) |

| Thermal overload factor | 0,05 | 0,05 | 0,05 | 0,05 | 0,05 | 0,05 | 0,05 | 0,05 | 0,05 | 0,05 | 0,05 | 0,05 | 0,05 | 0,05 | 0,05 | 0,05 | 0,05 |

| Frequency | 50/60 Hz | 50/60 Hz | 50/60 Hz | 50/60 Hz | 50/60 Hz | 50/60 Hz | 50/60 Hz | 50/60 Hz | 50/60 Hz | 50/60 Hz | 50/60 Hz | 50/60 Hz | 50/60 Hz | 50/60 Hz | 50/60 Hz | 50/60 Hz | 50/60 Hz |

| Protection degree | IP-00 | IP-00 | IP-00 | IP-00 | IP-00 | IP-00 | IP-00 | IP-00 | IP-00 | IP-00 | IP-00 | IP-00 | IP-00 | IP-00 | IP-00 | IP-00 | IP-00 |

| Cooling | AN | AN | AN | AN | AN | AN | AN | AN | AN | AN | AN | AN | AN | AN | AN | AN | AN |

| Ambient temperature | 45 ºC | 45 ºC | 45 ºC | 45 ºC | 45 ºC | 45 ºC | 45 ºC | 45 ºC | 45 ºC | 45 ºC | 45 ºC | 45 ºC | 45 ºC | 45 ºC | 45 ºC | 45 ºC | 45 ºC |

| Temperature rise | Class F – 155ºC | Class F – 155ºC | Class F – 155ºC | Class F – 155ºC | Class F – 155ºC | Class F – 155ºC | Class F – 155ºC | Class F – 155ºC | Class F – 155ºC | Class F – 155ºC | Class F – 155ºC | Class F – 155ºC | Class F – 155ºC | Class F – 155ºC | Class F – 155ºC | Class F – 155ºC | Class F – 155ºC |

| Insulation | Class H – 180ºC | Class H – 180ºC | Class H – 180ºC | Class H – 180ºC | Class H – 180ºC | Class H – 180ºC | Class H – 180ºC | Class H – 180ºC | Class H – 180ºC | Class H – 180ºC | Class H – 180ºC | Class H – 180ºC | Class H – 180ºC | Class H – 180ºC | Class H – 180ºC | Class H – 180ºC | Class H – 180ºC |

| Windings | Class HC – 200 ºC | Class HC – 200 ºC | Class HC – 200 ºC | Class HC – 200 ºC | Class HC – 200 ºC | Class HC – 200 ºC | Class HC – 200 ºC | Class HC – 200 ºC | Class HC – 200 ºC | Class HC – 200 ºC | Class HC – 200 ºC | Class HC – 200 ºC | Class HC – 200 ºC | Class HC – 200 ºC | Class HC – 200 ºC | Class HC – 200 ºC | Class HC – 200 ºC |

| Test voltage | 3 kV (1 min, 50 Hz) | 3 kV (1 min, 50 Hz) | 3 kV (1 min, 50 Hz) | 3 kV (1 min, 50 Hz) | 3 kV (1 min, 50 Hz) | 3 kV (1 min, 50 Hz) | 3 kV (1 min, 50 Hz) | 3 kV (1 min, 50 Hz) | 3 kV (1 min, 50 Hz) | 3 kV (1 min, 50 Hz) | 3 kV (1 min, 50 Hz) | 3 kV (1 min, 50 Hz) | 3 kV (1 min, 50 Hz) | 3 kV (1 min, 50 Hz) | 3 kV (1 min, 50 Hz) | 3 kV (1 min, 50 Hz) | 3 kV (1 min, 50 Hz) |

| Standards | IEC/EN/UNE-EN 60076-6, CE | IEC/EN/UNE-EN 60076-6, CE | IEC/EN/UNE-EN 60076-6, CE | IEC/EN/UNE-EN 60076-6, CE | IEC/EN/UNE-EN 60076-6, CE | IEC/EN/UNE-EN 60076-6, CE | IEC/EN/UNE-EN 60076-6, CE | IEC/EN/UNE-EN 60076-6, CE | IEC/EN/UNE-EN 60076-6, CE | IEC/EN/UNE-EN 60076-6, CE | IEC/EN/UNE-EN 60076-6, CE | IEC/EN/UNE-EN 60076-6, CE | IEC/EN/UNE-EN 60076-6, CE | IEC/EN/UNE-EN 60076-6, CE | IEC/EN/UNE-EN 60076-6, CE | IEC/EN/UNE-EN 60076-6, CE | IEC/EN/UNE-EN 60076-6, CE |

| Mounting | Screws | Screws | Screws | Screws | Screws | Screws | Screws | Screws | Screws | Screws | Screws | Screws | Screws | Screws | Screws | Screws | Screws |

| Includes | Bimetal thermal protection | Bimetal thermal protection | Bimetal thermal protection | Bimetal thermal protection | Bimetal thermal protection | Bimetal thermal protection | Bimetal thermal protection | Bimetal thermal protection | Bimetal thermal protection | Bimetal thermal protection | Bimetal thermal protection | Bimetal thermal protection | Bimetal thermal protection | Bimetal thermal protection | Bimetal thermal protection | Bimetal thermal protection | Bimetal thermal protection |

| Weight | 2,3 kg | 3,5 kg | 3,6 kg | 3,7 kg | 4,3 kg | 5 kg | 5,7 kg | 6,6 kg | 8,1 kg | 8,8 kg | 11,4 kg | 14,2 kg | 17 kg | 21,6 kg | 27,6 kg | 32,7 kg | 41 kg |

| Dimensions (AxBxCxDxE) | 150x180x185x49x100 mm 6Ø | 150x190x185x59x100 mm 6Ø | 150x190x185x59x100 mm 6Ø | 150x190x185x59x100 mm 6Ø | 150x195x185x64x100 mm 6Ø | 150x200x185x69x100 mm 6Ø | 150x205x185x74x100 mm 6Ø | 150x210x185x79x100 mm 6Ø | 150x220x185x89x100 mm 6Ø | 150x225x185x94x100 mm 6Ø | 180x220x220x89x120 mm 6Ø | 180x235x220x104x120 mm 6Ø | 180x250x220x119x120 mm 6Ø | 180x275x220x155x120 mm 6Ø | 240x275x320x114x160 mm 6Ø | 240x290x320x129x160 mm 6Ø | 240x300x320x154x160 mm 9Ø |

| Quote / Buy |

How to buy?

You can buy online if you are located in one of this countries: Austria, Croatia, Czech Republic, Finland, France, Germany, Greece, Hungary, Ireland, Italy, Lithuania, Luxembourg Poland, Slovakia and Sweden.

Special fabrications

We build transformers and inductive elements tailored to your needs.

Explain your needs and our engineers will create a solution adapted to your company.